Your portable diesel generator is more than just a piece of equipment; it's your reliable partner when the lights go out, the job site needs power, or adventure calls. But like any good partner, it needs a little care to stay at its best. This Portable Diesel Generator Maintenance Guide is designed to demystify the upkeep, ensuring your generator offers years of dependable service and truly stands the test of time.

Forget complicated jargon or tedious instructions. We're going to break down generator maintenance into practical, actionable steps that anyone can follow. Keeping your machine in top shape isn't just about preventing breakdowns; it's about preserving your investment, maintaining efficiency, and ensuring safety for you and your family or crew.

At a Glance: Key Takeaways for Generator Longevity

- Your User Manual is King: Always consult your generator’s specific manual first for precise instructions, schedules, and model-specific details.

- Routine is Critical: Regular inspections, oil changes, and cleaning prevent rapid wear and tear, saving you money in the long run.

- Know Your Role: You’ll handle accessible tasks like oil checks and cleaning; professionals are for complex engine or electrical work.

- Listen, Look, Smell: A quick sensory check before or after each use can catch minor issues before they become major problems.

- Cleanliness is Next to Power-ness: Regular cleaning, done correctly (no power washers!), prevents dirt and debris from impacting performance.

- Fluid & Filter Fundamentals: Consistent oil changes and air filter maintenance are non-negotiable for engine health.

- Spark & Safety Checks: Don't forget spark plugs, arresters, and critical safety features like GFCI outlets.

- Don't Overlook the Battery: For electric start models, a healthy battery means reliable starts.

- Know When to Call a Pro: Some tasks, like valve clearance checks, are best left to experienced technicians if you're not confident.

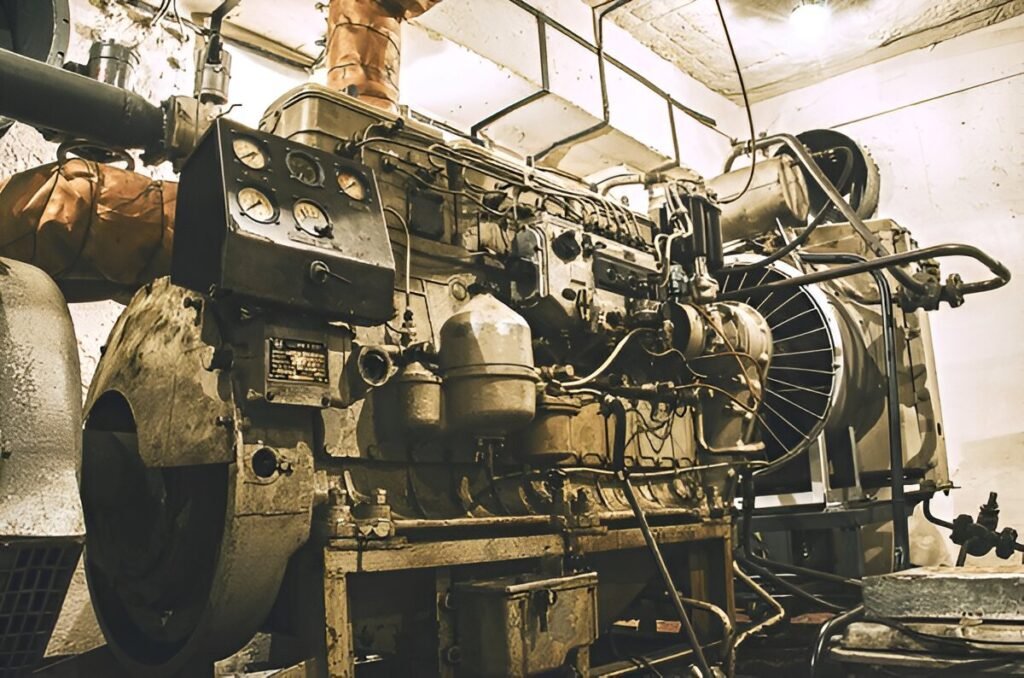

Why Your Generator Deserves Regular TLC: The Longevity Equation

Think of your portable diesel generator as a small, powerful engine designed to work hard in often challenging conditions. Without regular attention, it’s susceptible to rapid deterioration. Just like a car, proper maintenance isn't merely a suggestion—it's the bedrock of longevity, peak performance, and cost savings. Ignoring it leads to frequent repairs, diminished output, and ultimately, premature replacement, which nobody wants.

Generator maintenance is a blend of simple routines and periodic checks: inspecting components, changing fluids, cleaning away grime, and ensuring the engine's core functions are pristine. Each task plays a vital role in preventing wear and tear, extending the life of critical parts, and ensuring that when you hit the start button, your generator roars to life exactly as it should.

Your Maintenance Playbook: The User Manual & Schedule

Before you lay a finger on your generator, grab its user manual. This isn't just a thick booklet to skim; it's your generator's specific bible, detailing everything from oil types to torque specifications. General guidelines are helpful, but your manual offers model-specific instructions that trump all else. Always consult it before undertaking any maintenance task.

Who Does What? Unpacking Maintenance Responsibility

Maintenance tasks often fall into two camps:

- User Responsibilities: These are the easily accessible tasks you can perform, such as checking oil levels, refilling fuel, cleaning exterior components, and sometimes replacing spark plugs or air filters.

- Professional Responsibilities: More complex or inaccessible components, like internal engine adjustments or intricate electronic circuit diagnostics, are best left to certified technicians. Your manual will often clarify this distinction.

Sticking to a Schedule: The Path to Predictability

Your user manual isn't just a how-to guide; it’s also your maintenance scheduler. It outlines periodic tasks, recommended frequencies (e.g., every 50 hours, annually), and explicitly states which tasks are user-friendly versus those requiring a professional.

Pro Tip: Mark these dates on your personal calendar or use a digital reminder. Some modern generators even feature helpful maintenance reminders directly on their control panels, often tracking hours of use for oil changes or air filter replacements. However, don't rely solely on these; a quick manual oil check before each use remains essential.

Smart Prep: Maintenance Kits and CO Sensors

To simplify your routine, consider manufacturer-provided maintenance kits. These often bundle common spare parts like air filters and spark plugs, along with the correct oil. While convenient, always compare the kit's value against purchasing individual OEM (Original Equipment Manufacturer) parts. Sometimes, buying components separately offers better quality or value.

Modern generators often include a CO (Carbon Monoxide) sensor for crucial safety. Your manual will detail its maintenance needs, which might include specific notification mechanisms (e.g., flash frequencies indicating remaining lifespan). Adhering to these guidelines is vital for ensuring this life-saving feature remains operational.

The "Before or After Each Use" Ritual: Your General Inspection

Even with a strict maintenance schedule, performing a quick general inspection before or after each use is non-negotiable. Maintenance schedules can't account for accelerated wear in harsh conditions or unexpected issues. This rapid, sensory-driven check is your first line of defense, helping you spot potential problems early, often preventing minor nuisances from escalating into costly repairs.

Here’s what your quick check should cover:

- Engine Performance: Start it up. Does it run smoothly? Can it handle a typical load without struggling? Is there any unusual trouble starting?

- Physical Condition: Give your generator a once-over. Are all screws and bolts tight? Check for any cracks, dents, or obvious damage on the body.

- Sounds and Smells: Listen for any unusual sounds under load—knocking, grinding, or excessive vibration. Sniff around for strange odors, especially a "burnt toast" smell, which could indicate carbon buildup.

- Leaks: Scan the ground beneath and around the generator. Are there any visible oil or gas leaks? Even small drips need investigation.

- Controls and Outlets: Briefly check that all buttons and switches operate correctly. Inspect the outlets—they should be clean, provide good contact, and plugs should sit snugly.

- Extension Cords: If you’re using them, ensure your extension cords are in good condition, with sealed insulation, no stiff or brittle sections, and absolutely no exposed wiring. Safety first!

The Core Regimen: Regular Maintenance Tasks

Remember: Your generator's user manual is your ultimate authority. The guidelines below are general best practices; always defer to your specific model’s instructions.

1. Cleaning Your Generator: More Than Just a Pretty Face

Dirt, dust, and debris aren't just an aesthetic problem; they can clog cooling fins, interfere with moving parts, and even cause electrical shorts. Regular cleaning is fundamental.

- Equipment You'll Need: Water, mild soap/detergent, soft cloths/rags, a kitchen sponge, an extra-soft toothbrush, specialized tube brushes for tight spots, and a compressed air can. For tough stains, rubbing alcohol or even a can of coke can be surprisingly effective.

- Frequency: Ideally, before or after each use, especially if used in dusty or dirty environments.

- The Steps to a Pristine Machine:

- Safety First: Ensure the generator is off, cool, and disconnected from any fuel source (if draining for storage, otherwise just ensure fuel cap is secure). Disassemble any easily removable parts as instructed in your manual.

- No Liquids on Electronics: Absolutely avoid spraying water or liquid directly onto electronic components, the control panel, or the engine’s electrical parts.

- Exterior & Accessible Interior: Use a damp cloth with soap or detergent to wipe down the exterior. For accessible interior areas, gently clean away grime. NEVER use a power washer or a garden hose on your generator. The high pressure can force water into sensitive areas, causing damage or corrosion.

- Tough Stains & Carbon Buildup: For stubborn greasy stains, a small amount of rubbing alcohol or even paint thinner (as a last resort, sparingly, and with caution) on a rag can work. For carbon buildup on specific, disassemble-able metal parts (like a spark arrester), a small wire brush can be effective.

- The "Coke" Method (Use with Extreme Caution): For extremely tough stains on submergeable metal parts only, some mechanics have used coke to dissolve buildup. If you choose this highly unconventional method, ensure the part is completely submerged, then thoroughly rinsed with clean water and dried completely afterward to prevent stickiness and corrosion. This is generally for parts that can be fully removed and are not part of the primary engine block or electrical system.

- Drying is Key: After cleaning with any liquid, allow the unit to dry thoroughly before reassembling or operating. Moisture can cause significant issues.

- Tools & Their Uses:

- Cloths/Rags: Your go-to for general wiping, minimizing surface damage.

- Softer Brushes: Excellent for dislodging tougher grime and carbon buildup in crevices. Tube brushes are fantastic for exhaust ports or cooling fins.

- Compressed Air: Best for delicate electronics, control panels, and for blowing dust out of air filters (from the inside out).

- Toothbrush: Its small head and soft bristles make it incredibly versatile for hard-to-reach spots.

- Kitchen Sponge: Great for exterior surfaces and for absorbing excess cleaning agents.

2. Oil Check and Replacement: The Engine's Lifeblood

Engine oil lubricates, cools, and cleans your engine. Proper oil levels and clean oil are paramount for engine longevity.

- Equipment You'll Need: The correct type and viscosity of engine oil (check your manual!), a funnel (optional but highly recommended), your generator’s dipstick, and appropriate disassembly tools for draining.

- Frequency:

- Oil Check: Before or after each use.

- Oil Change: Every 50-100 hours of use, or every 3-6 months if the generator sits idle.

- Break-in Period: A new generator requires more frequent oil changes during its initial break-in period (consult your manual for exact intervals).

- Steps for Oil Maintenance:

- Check Level: Ensure the generator is on level ground and cool. Remove the dipstick, wipe it clean, reinsert it fully (don't screw it in unless your manual specifies), then remove it again to check the oil level against the manufacturer's markings. Top up if necessary.

- Changing the Oil (Warm is Best): Run the generator for a few minutes to warm the oil, which makes it drain more completely. Place a drain pan beneath the oil drain plug (usually distinct from the filler cap). Remove the plug. For a more thorough drain, you might gently lean the generator to ensure all old oil escapes.

- Refill Correctly: Once drained, replace the drain plug securely. Using a funnel, slowly add new, manufacturer-recommended oil. Check the level frequently with the dipstick, ensuring you reach the correct fill line without overfilling. Overfilling can cause engine damage and excessive pressure.

3. Cleaning and Replacing Air Filters: Breathing Easy

A clean air filter is essential for proper engine combustion and preventing dirt from entering the engine.

- Equipment You'll Need: A soft cloth, kitchen sponge, compressed air can, mild cleaning liquid (soap water or alcohol), and disassembly tools.

- Frequency: Every 50-100 hours of use, or more frequently if operating in very dusty conditions.

- Important Warning: Some paper air filters are designed for replacement only and cannot be cleaned. Always check your user manual to confirm if your filter is cleanable or needs to be replaced.

- Steps for Air Filter Service:

- Removal: Locate and carefully remove the air filter as per your manual’s instructions.

- Cleaning (if applicable):

- Compressed Air: For paper filters that can be cleaned, gently blow compressed air through the filter from the inside out (opposite to normal airflow) to dislodge dust and debris. Do not use high pressure, as it can damage the filter material.

- Washing (for foam filters/some paper types): If your manual permits, soak the filter in soap water or rubbing alcohol. Gently scrub with a soft cloth or kitchen sponge. Avoid using stiff brushes, which can tear the filter material.

- Oiling Foam Filters: Some manuals (e.g., Honda) recommend dipping clean, dry foam filters in fresh engine oil, then gently squeezing out the excess. This helps trap finer particles.

- Drying: Ensure the filter is completely dry before reinstalling.

- Replacement: If your filter is damaged, excessively dirty, or non-cleanable, replace it with a new, manufacturer-recommended part. It’s always smart to keep a spare air filter on hand.

4. Spark Arrester and Spark Plug Service and Replacement: Ignition Essentials

These two components are critical for safe operation and reliable starting.

- Equipment You'll Need: A spare spark plug/arrester, a small wire brush, a feeler gauge (wire-type is best for spark plugs), a screwdriver, and a spark plug wrench.

- Frequency:

- Cleaning: Every 50-100 hours of use, or as needed if you notice performance issues.

- Replacement: Every 300 hours of use, after 1 year when idle, or based on visual inspection (damage, excessive carbon buildup).

- Steps for Spark Service:

- Keep Spares: Always have a spare spark plug and, if applicable, a spark arrester on hand.

- Removal: Follow your manual to safely remove the spark arrester and spark plug. Clean the surrounding area thoroughly before removal to prevent debris from falling into the engine.

- Spark Arresters:

- Cleaning: Use a small wire brush to remove carbon buildup from the screen.

- Inspection: Check for any tears, holes, or damage to the screen. If it's compromised, replace it immediately. A damaged spark arrester is a fire hazard.

- Spark Plugs:

- Cleaning: Gently clean off carbon deposits with a small wire brush.

- Gap Check: Use a feeler gauge (wire-type is ideal) to check the spark plug gap against the manufacturer's specifications (found in your manual). If the gap is incorrect or the plug shows signs of significant wear, fouling, or damage (cracked porcelain, melted electrode), replace it.

- Installation: When reinstalling, thread the spark plug into the cylinder head by hand first to avoid cross-threading. Once finger-tight, use a spark plug wrench to tighten it to the specified torque (check your manual). Never leave a spark plug loose, as this can cause misfires and engine damage. Use only manufacturer-recommended spark plugs.

5. GFCI Check: Ensuring Electrical Safety

Ground Fault Circuit Interrupter (GFCI) outlets are a vital safety feature, protecting users from electrical shock.

- Equipment You'll Need: Your finger, possibly a simple lamp or test light to verify.

- Frequency: Before each use.

- Steps for GFCI Test:

- Test Button: Locate the "TEST" button on your generator's GFCI outlets.

- Trip the Circuit: Press the "TEST" button firmly. This should trip the internal ground connection.

- Verify Trip: The "RESET" button should pop out, or an indicator light should change. If you have a lamp plugged into the outlet, it should switch off.

- Reset: Press the "RESET" button to restore power.

- Troubleshooting: If the GFCI fails to trip, or if it trips but won't reset, do not use the generator. Ensure the generator is properly grounded as per your manual. If issues persist, seek professional help immediately. This is a critical safety feature.

6. Servicing an Electric Starter: Powering Up Easily

If your diesel generator features an electric start, its battery needs attention.

- Equipment You'll Need: A spare battery (optional, but good for quick replacement), a battery charger compatible with your generator’s battery, and disassembly tools.

- Frequency: As necessary, or periodically check charge and condition.

- Steps for Electric Starter Service:

- Inspection: Regularly inspect the battery for any signs of leakage, corrosion around the terminals, or physical damage.

- Charge: If the battery struggles to hold a charge or if the generator cranks slowly, connect it to a suitable charger. Follow the charger’s instructions and ensure it’s appropriate for your battery type.

- Replacement: If the battery is leaking, severely corroded, or no longer holds a charge after proper charging, it needs to be replaced. Always use a manufacturer-recommended replacement battery to ensure compatibility and performance.

- Terminal Care: Keep battery terminals clean and tight to ensure good electrical contact.

7. Changing a Fuse: A Quick Fix for Overloads

Fuses are safety devices designed to protect your generator's electrical circuits from overloads.

- Equipment You'll Need: A spare fuse of the exact correct rating, and disassembly tools if the fuse is not easily accessible.

- Frequency: As necessary (during troubleshooting a power issue). Fuses do not require periodic checks; they either work or they're blown.

- Steps for Fuse Replacement:

- Identify Blown Fuse: If a circuit stops working, a blown fuse (often visible as a broken wire inside) is a common culprit.

- Locate & Remove: Consult your manual to locate the fuse box or individual fuse. Carefully remove the blown fuse.

- Replace with Exact Match: It is absolutely critical to replace a blown fuse with one of the exact same amperage rating. Using a fuse with a higher rating can lead to serious electrical damage or fire, as it won't trip when an overload occurs.

- Keep Spares: It's wise to keep spare fuses for all ratings your generator uses.

8. Checking Valve Clearance: An Advanced Engine Health Check

Valve clearance ensures that your engine's valves open and close at the correct times and fully seal when closed. Incorrect clearance can lead to poor performance, excessive wear, or engine damage.

- Equipment You'll Need: A feeler gauge, and specific disassembly tools for accessing the valve cover and internal engine components.

- Frequency: Every 50-100 hours, or as recommended in your manual.

- Important Note: This task is for a cool engine. It requires a certain level of mechanical aptitude and confidence. If you're unsure, it is advisable to contact a professional.

- Steps for Valve Clearance Check (General Overview):

- Engine Cool & Ready: Ensure the generator engine is completely cool.

- Access: Consult your manual to locate the engine's valves and identify how to properly remove the spark plug and valve cover.

- Position Valves: Your manual will specify how to rotate the crankshaft to position the valves correctly for measurement (usually at Top Dead Center (TDC) on the compression stroke for specific cylinders, or with the non-operating stem compressing the spring).

- Measure: Using a feeler gauge, slide the appropriate blade between the uncompressed valve stem and its corresponding rocker arm or tappet. Compare this measurement to the manufacturer's specified clearance in your manual.

- Interpret: If the clearance is too loose (too much gap) or too tight (too little gap), it's problematic. Adjusting valve clearance typically involves specific tools and knowledge to turn adjusting screws or replace shims. This is where professional help is often recommended.

- Reassembly: Once measured (and adjusted, if done by a professional), reassemble the valve cover and other components, ensuring gaskets are seated correctly to prevent oil leaks.

When to Call in the Pros

While this guide empowers you to handle most routine maintenance, some issues or tasks are best left to experienced, certified technicians. This includes:

- Persistent Performance Issues: If your generator is still running rough, refusing to start, or showing consistent error codes after you've performed basic maintenance.

- Electrical Problems: Beyond simple fuse changes or GFCI resets, any complex electrical faults should be handled by an expert.

- Fuel System Issues: Problems with the carburetor (for gas generators, though diesel systems have their own complexities), fuel pump, or fuel injectors often require specialized tools and knowledge.

- Deep Engine Diagnostics: Any issues requiring extensive engine disassembly, like major internal component repairs beyond valve clearance checks, are professional territory.

- Warranty Concerns: Attempting complex repairs yourself might void your warranty.

When in doubt, it’s always better to err on the side of caution and consult a professional. They have the expertise, specialized tools, and genuine parts to diagnose and fix issues safely and effectively. You can also explore portable diesel generators on our site for more resources.

Fueling Your Confidence: A Maintained Generator is a Reliable Generator

You've invested in a powerful tool, and with a bit of consistent care, that tool will serve you faithfully for years. Following this comprehensive portable diesel generator maintenance guide isn't just about ticking boxes; it's about building a relationship of trust with your equipment. Each oil change, every air filter clean, and every GFCI test contributes to a generator that you know will kick into gear when you need it most.

By prioritizing your user manual, embracing a regular inspection routine, and tackling maintenance tasks with confidence, you're not just preventing problems—you're securing peace of mind. So go ahead, get your hands a little dirty, and enjoy the dependable power that only a well-maintained diesel generator can provide.